Thesis Topics

DynLab Will Help You Choose Thesis Topic and Supervision

DynLab provides students with supervision of bachelor’s and master’s theses focused on topics related to rotordynamic analysis, design and measurement of rotating machines and their components.

The thesis topics are inspired by contemporary problems solved in engineering practice in the design and analysis of rotating equipment. Theses are supervised not only by professional lecturers of the institute, but also by industrial specialists and developers.

Thesis topics are not definite and may be adapted according to the students’ research focus or student-submitted topic suggestions.

Bachelor's Thesis Topics

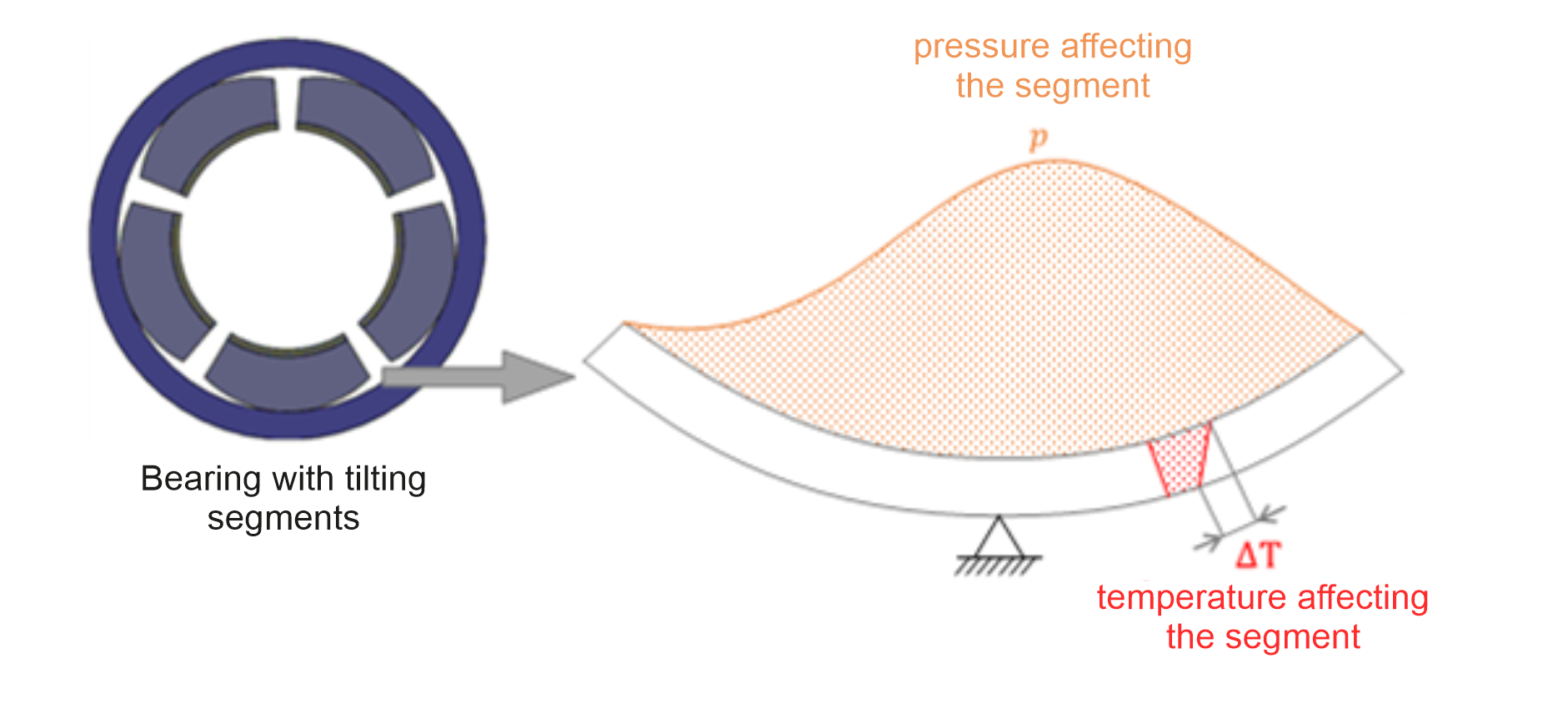

1. A simplified model of the pad deformation of the journal bearing

Tilting-pad bearings are used in high-speed devices. The properties of these bearings are often determined by calculation. Because the pads of the bearing are subjected to pressure and temperature during operation, the calculated results depend, among others, on the pad deformation. The task is to conduct a literature review and perform a simplified calculation of pad deformation.

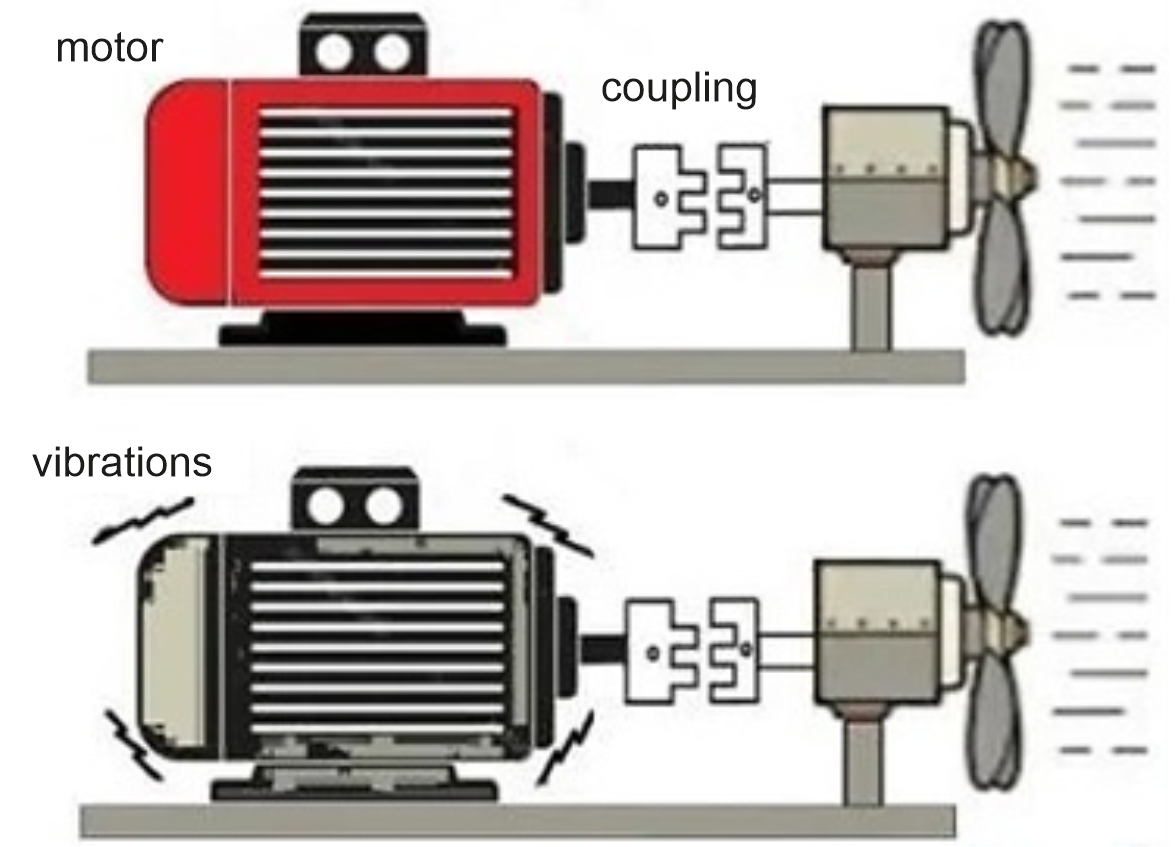

2. Design of a high-speed flexible coupling

Couplings are used not only to transmit torque from the motor but also to compensate for misalignment of the drive and driven shafts or possible vibrations. The task is to conduct a literature review and design a high-speed flexible coupling based on it.

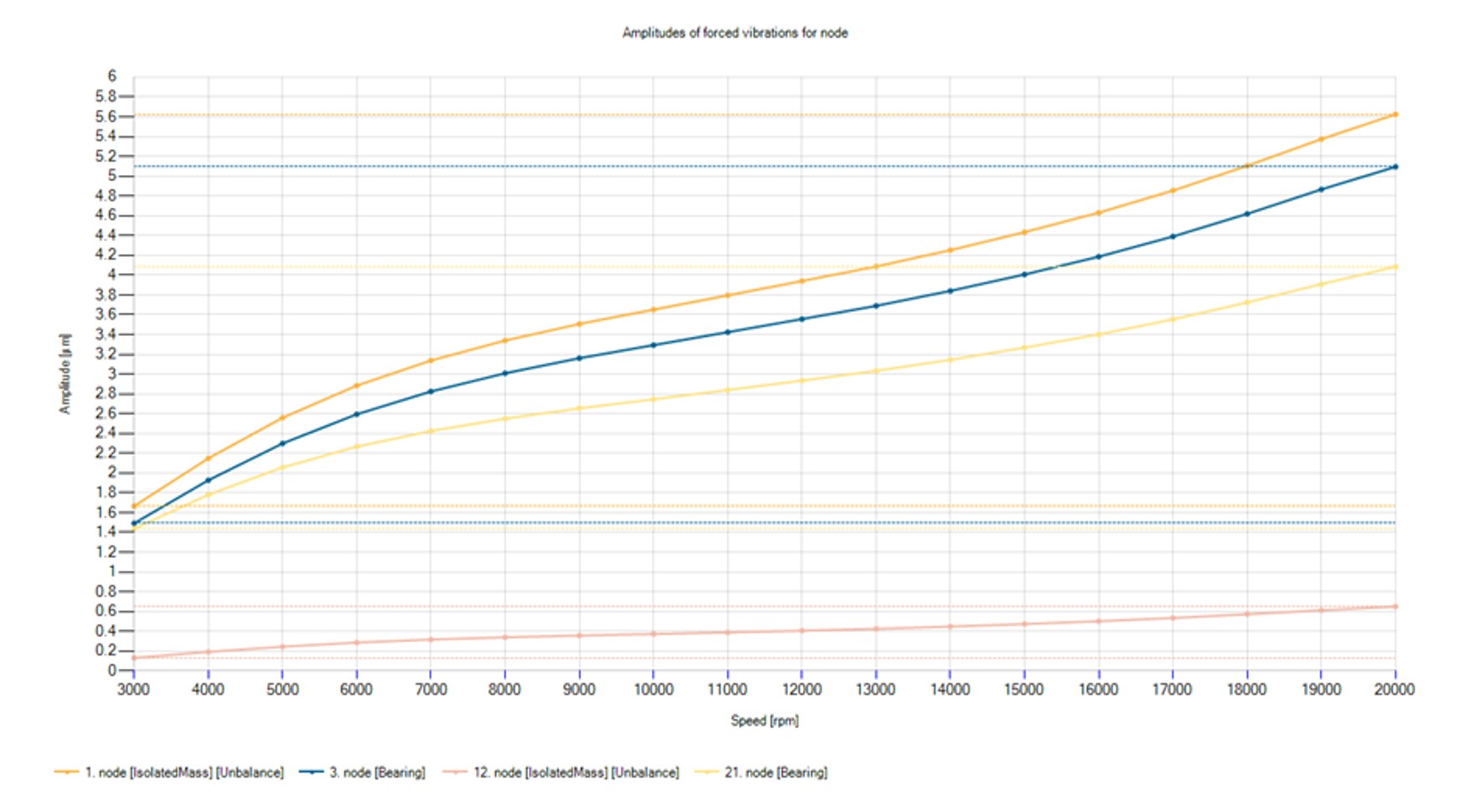

3. Comparison of programs for calculation of rotordynamics

The calculation of rotor dynamics is an integral part of the design of high-speed devices. This calculation can be performed in various commercial and open-source programs. The aim of the work is to search for available programs and compare their results concerning the selected example.

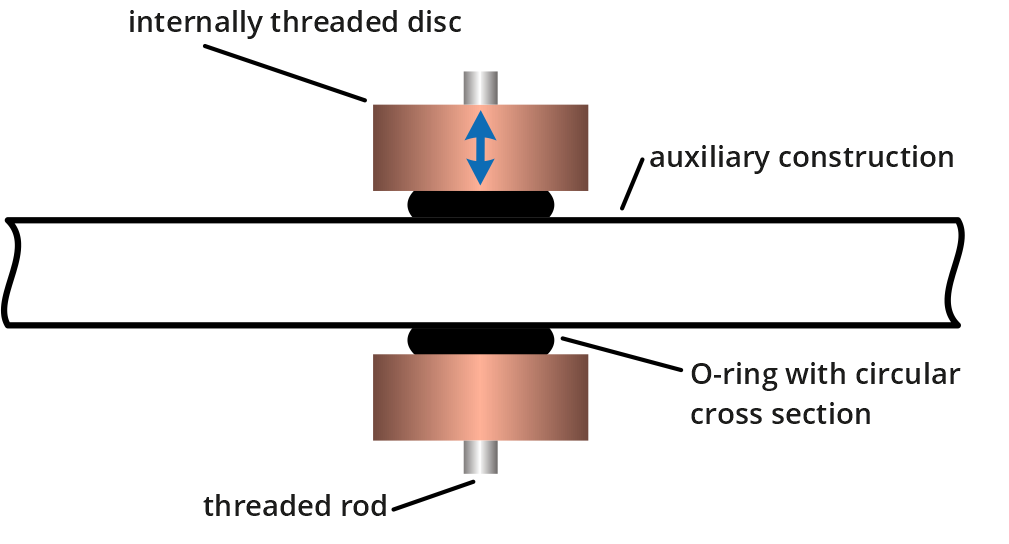

4. Design of equipment for measuring stiffness and damping of damping elements in bearings

Damping elements such as o-rings are often used in the supports of high-speed rotary machines. To determine the dynamic parameters of the support as a whole, it is necessary to know the stiffness and damping of these damping elements. The aim of the work is to perform a literature review and design a device for measuring the dynamic parameters of these damping elements.

Masters's Thesis Topics

1. Comparison of computational programs using FEM in the Python environment

2. Comparison of bearing capacity of a radial hydrodynamic bearing determined in the Ansys Fluent environment and according to the assumptions of Reynolds theory

3. Design of an optical rotational speed sensor for vacuum and pressure applications

4. Measurement of dynamic parameters of o-rings

5. Analysis of open-source software for calculating rotor dynamics

6. Device for measuring the permeability of materials for static and dynamic applications of bearings and seals

The materials used for aerostatic and dynamic seals and bearings show a certain degree of porosity. This porosity can have a different character, and as a result, its influence on the possibility of use for the given application may not be unambiguous. The goal of the work is to design and implement a simple measuring device and method of measuring porosity that would reflect the needs of aerostatic and aerodynamic applications of bearings and seals.

Research objectives:

- Computational model design

Experiment design - Design of measuring equipment

- Production of equipment using 3D printing

- Experiment execution and evaluation

7. Design of a composite rotor sleeve of a high-speed rotating machine

Currently, metal sleeves are widely used in high-speed machines, especially electric motors and generators, to fasten permanent magnets. The high density of the materials used necessitates the use of a thick sleeve at high speeds, which increases the gap between the rotor and stator magnets and thus reduces the efficiency of the machine. Furthermore, eddy currents are generated in the metals, resulting in a further influence on efficiency and thermal properties. The aim is therefore to eliminate these undesirable phenomena by replacing the metal material with a composite. The aim of the work is to design a composite sleeve using FEM-based calculations, to produce the designed piece and test the required properties.

Research objectives:

- Research of composite materials (types, distribution, production)

- Creation of a computational model of the sleeve

- Determination of the geometric parameters of the sleeve for the selected rotating machine

- Design and implementation of test equipment for testing the sleeve

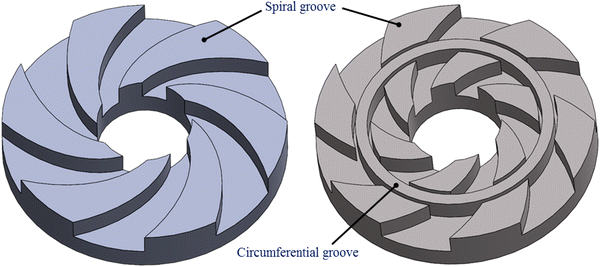

8. Design of a thrust bearing with spiral grooves including experimental verification

The goal is to use new knowledge and technologies to improve production, especially precision surface grooves used, for example, for axial aerodynamic bearings of high-speed machines. They usually work better with a higher number of grooves, which is limited by the production method and its accuracy.

Research objectives:

- Research of additive and subtractive methods of component production

- Experiment and production design (PVD, EE, AB and others)

- Performing calculations using FEM

- Conducting a validation experiment

9. Design and implementation of a finishing tool for micromachining components for rotating machines with nanometric accuracy

Modern rotating machines require precise dimensions of key components, these can be achieved by statistical selection in the case of mass production, or by an additional fine-grinding operation with nano-metric precision. For laboratory purposes, the goal of the work will be to design and implement a device that will be able to finish the surface of selected components with nanometric precision using a metallographic grinder. It will be a mechatronic assembly, and apart from the movement of the fine-brushed components, it will be necessary to add a method of precise measurement and others.

10. Design and automation of an abrasive machining tool for micromachining large surfaces of decimetric dimensions and micro engraving

There are cases requiring precise production with respect to the sampling depth or the repeatability of the dimensions defined by the prototype template. These are relatively large dimensions in the order of centimetres, but they must have precise machining repeatability in the order of units of micrometres or tens of nanometres. The goal of the work is to design and implement a 3D printer analogy for these applications, but instead of a print head, use a sandblasting nozzle with an abrasive.

Research objectives:

- Design and production (or modification of existing) equipment for surface treatment according to specifications

- Optimization of the production process in terms of material surface

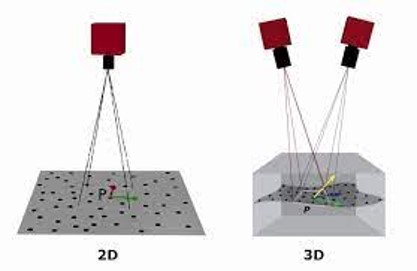

- Verification of achieved results using camera technology